Magnitogorsk Metallurgical Combine (MMK) Names IMS Messsysteme GmbH as “The Best Supplier 2021”

Represented by its russian subsidiary, IMS received this award as "The Best Supplier 2021" in the category "The Leader of Unique Digital Solutions for Production".

- enero, 2022

Alexander Radaev, IMS Service LLC, proudly accepts the “Best Supplier 2021” award

- Magnitogorsk Iron and Steel Works (MMK) honoured its most dependable business partners as its “Best Supplier 2021”

- IMS Messsysteme GmbH receives this award as "The Best Supplier 2021" in the category "The Leader of Unique Digital Solutions for Production"

- Today, measuring systems from the world market leader in Heiligenhaus are an integral part of production at all important production stages of the world's leading steel producer

In mid-December 2021, the Magnitogorsk Iron and Steel Works (MMK), one of the world’s leading steel manufacturers, honoured its most dependable business partners and winners of its “Best Supplier 2021” contest at a festive ceremony.

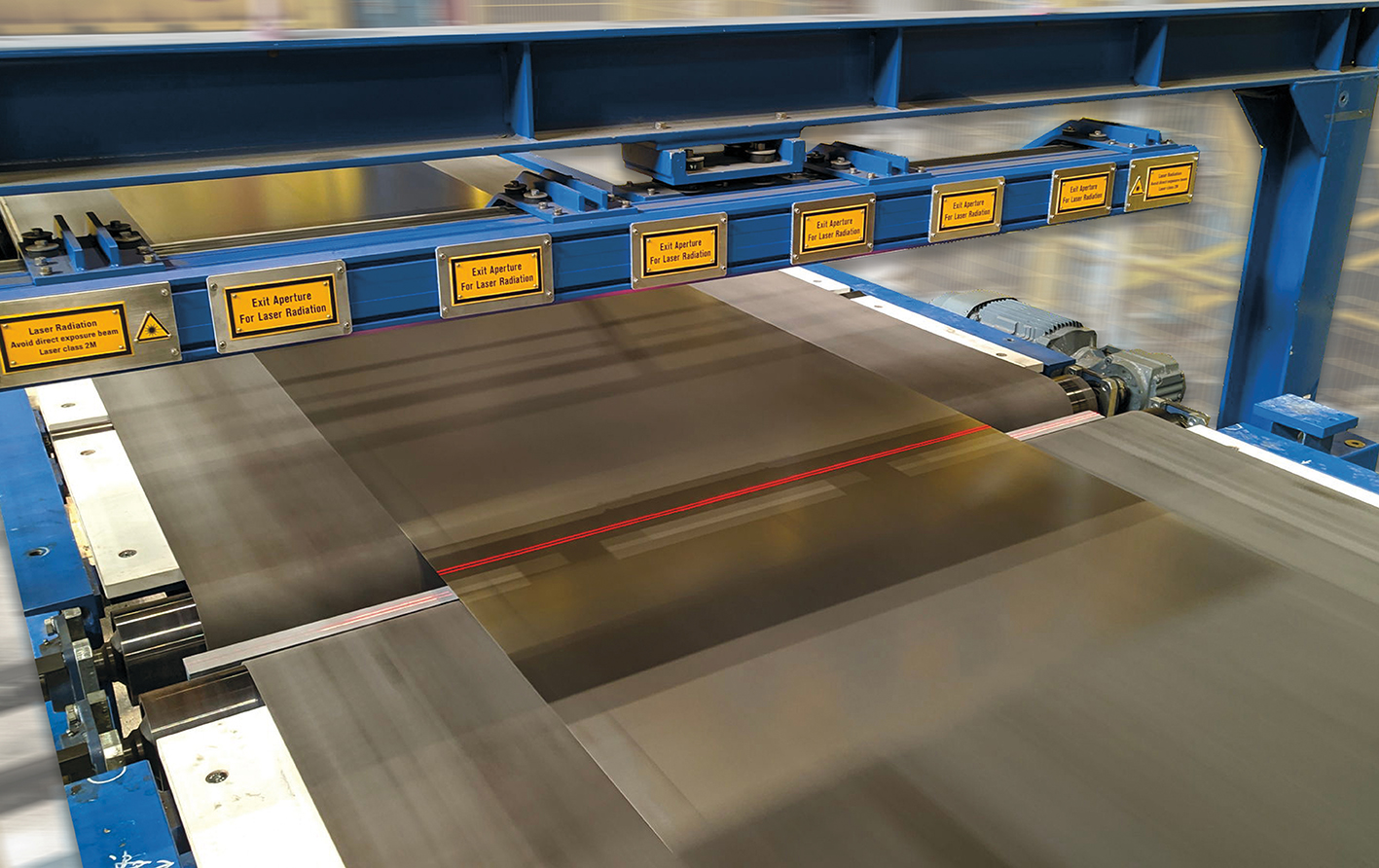

The partnership between IMS Messsysteme GmbH and Magnitogorsk Iron & Steel Works has enabled the successful installation of state-of-the-art measuring systems in MMK’s production facilities in recent years.

The honorary diploma and commemorative sculpture were presented with a strong handshake, symbolising the equally strong partnership between the two companies. MMK currently cooperates with a total of more than 2,250 active suppliers, from which the respective winners were selected and honoured in 13 categories in the course of the competition.

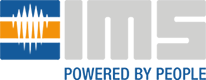

Manual inspection of flatness is no longer sufficient to guarantee the surface qualities required. Complete documentation of concrete measurement results as proof of quality is also simply impossible with this procedure.

Fully automated measurement, control and documentation of flatness and evenness is therefore a decisive success factor that not only significantly increases the quality of strips, sheets and plates, but also reduces critical factors for output such as the scrapping of defectively manufactured products.

Contact and Support

IMS Messsysteme GmbH, represented by its Russian subsidiary IMS Service LLC, received this award as “The Best Supplier 2021” in the category “The Leader of Unique Digital Solutions for Production”.

Today, the measuring systems of the world market leader form an integral part of production operations at all important production stages of the Magnitogorsk steel producer. Fast and reliable determination of all relevant parameters of material in the ongoing production process contributes significantly to the high quality of the end products and the worldwide success of the Russian company.

IMS Messsysteme GmbH is proud of the award it has received and the associated confidence in its systems, which once again underpins the leading position of the Heiligenhaus-based company on the market for measuring systems for metallurgical processes.

To enable these cameras to recognise the surface quality of the rolled products and to evaluate unflatness as height differences, straight laser lines, which deform in the case of unflatness, are projected on to the material. The cameras detect these deformations, which are converted into exact measured values by downstream software, and thus document the concrete surface profile of the material.

In the case of very shiny surfaces, as is the case with aluminium, for example, these laser lines are scattered at different angles by the reflection of the material and are not recorded with the same intensity throughout.

If the camera is positioned approximately vertically above these areas, the cameras do not experience such scatter loss. Towards the edges of the strip, however, which also act as the limits of the camera angle, there are undesirable measurement inaccuracies.

The CCS flatness/evenness measuring system of the world’s leading manufacturer IMS Messsysteme GmbH is based on a measuring technique that is unique on the market, in which a large number of individual cameras are connected in series to form clusters.

The distance between the cameras is 20 mm. To detect the flatness of a strip 2 m wide, 100 of these high-tech cameras are used, each of which detects only a narrow area of the strip width and is thus positioned almost vertically above the material, thereby avoiding measurement inaccuracies due to scatter losses. In other words, a technical measuring principle which, due to its design, guarantees exact flatness and evenness measurement even on high-gloss materials such as aluminium.