3D surface inspection directly after the stretch-reducing mill

New installation and commissioning of the 4-channel wall thickness measurement system retrofitted with surcon 3D surface inspection at voestalpine Tubulars GmbH & Co. KG successfully completed

- julio, 2022

IMS Messsysteme GmbH and voestalpine Tubulars GmbH & Co. KG set new standards in the early detection of surface defects

- Combination of two completely different measuring techniques in a single system

- No need to create additional installation space for another measuring point

- Simultaneous determination of wall thickness, diameter and profile, temperature as well as surface defects at the same measuring point, with the same pipe length reference

- Surface inspection moves one step closer to the manufacturing process

Another milestone in the decades-long synergetic business relationship between IMS Messsysteme GmbH, Heiligenhaus, Germany, and voestalpine Tubulars GmbH & Co. KG, Kindberg, Austria has been achieved:

Potential surface defects on the hot-rolled finished tubes from Kindberg will now be detected immediately behind the stretch-reducing mill, bringing their detection another step closer to the manufacturing process.

With this success, voestalpine Tubulars once again distinguishes itself as a pioneer in the production of seamless rolled tubes. In terms of quality, the Austrian company repeatedly relies on the proven measuring technology of the world market leader IMS and sets new standards in the industry.

Contact and Support

What makes the joint project so special and in line with voestalpine’s motto “one step ahead” is the combination of two completely different measuring technologies in a single system.

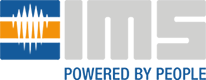

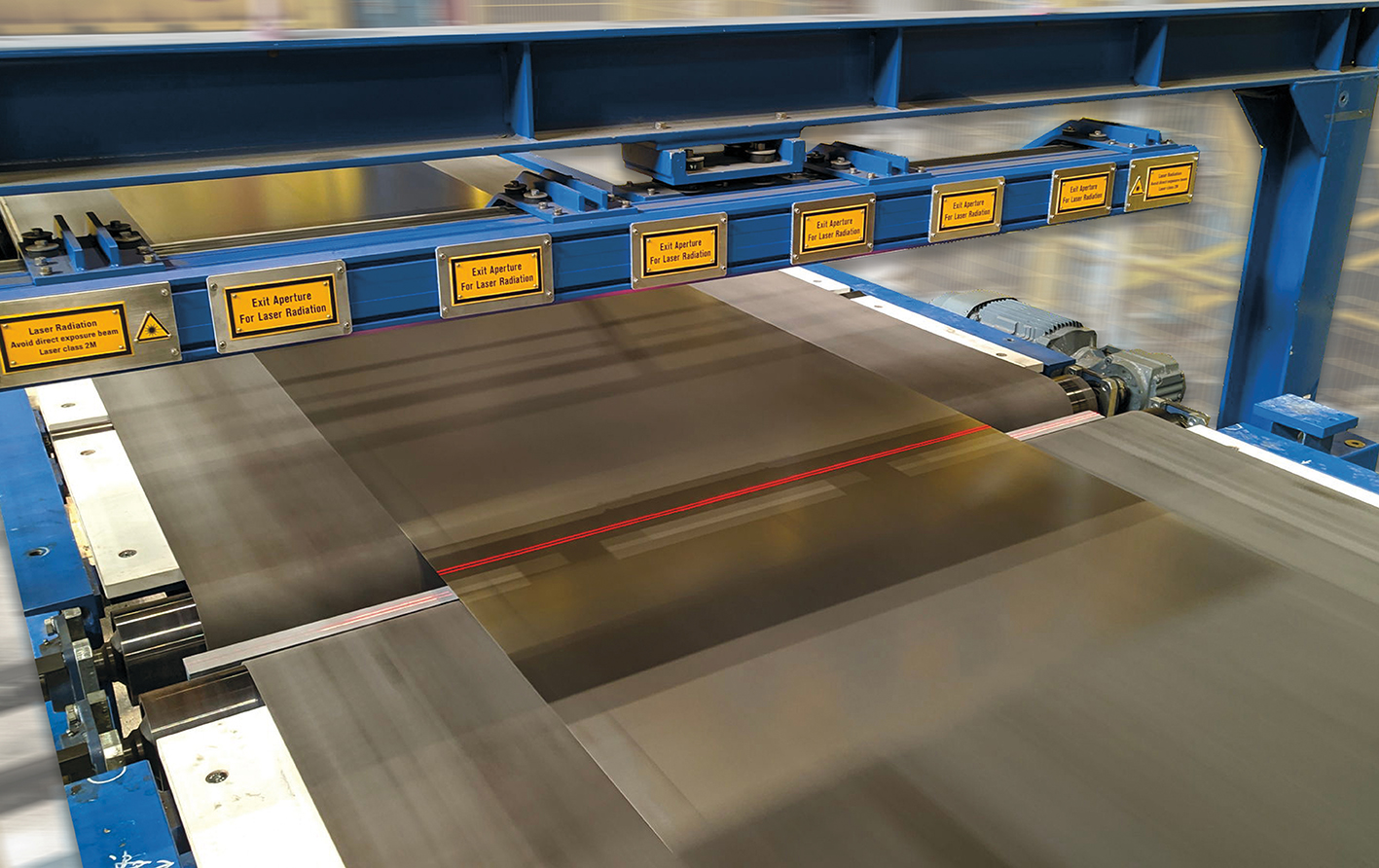

For this purpose, the radiometric components of the existing 4-channel measuring system were mounted together with the camera and laser technology of surcon 3D surface inspection in a new housing that is only slightly larger in terms of dimensions.

The advantages of this revolutionary fusion of two complex technologies are obvious:

• All measurement data such as wall thickness, diameter and profile, temperature and surface defects are determined simultaneously at the same measurement location and have the same tube length reference

• The existing IMS measuring location can continue to be used as before

• There is no need to create additional space for another measuring point

• Only minor adjustments to the roller table elements and their surroundings are necessary

The feedback from Kindberg is consistently positive and confirms to IMS Messsysteme GmbH the complete fulfillment of the customer requirement:

Figure 1: Thomas Brunner, Assistant Production Manager Tube Rolling Mill, voestalpine Tubulars (Quelle: voestalpine Tubulars)

It is impossible to imagine everyday production without the surface inspection system after only a short learning phase. From our point of view, the surface finish is an essential component, in addition to the outside diameter and wall thickness measurement, to produce a high-quality product.

Thomas Brunner, Assistant Production Manager Tube Rolling Mill, voestalpine Tubulars

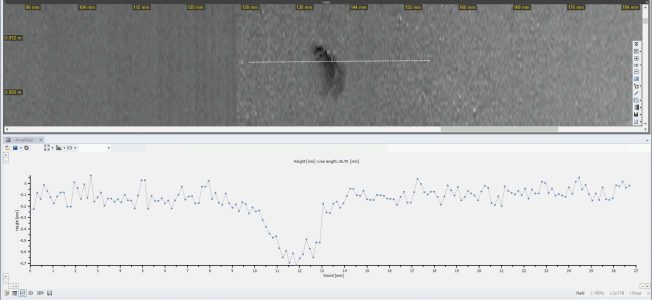

The response time to eliminate the source of defects on the aggregates, such as buildup on the rolls of the mill stands, can be significantly reduced as well as the scrap rate.

“The new surface inspection system from IMS saves us from performing production steps we don’t need.”

The location and type of detected surface defects can be immediately communicated to downstream production areas. If serious defects are detected, which inevitably lead to rejects during quality control, the subsequent production steps can be avoided. Periodically occurring defects on the tube surface defects are reliably detected, identified, and can be quickly eradicated.

Figure 2: Photo of visible defect “impression” on the tube surface (Source: voestalpine Tubulars)

Figure 3: Measurement data surcon 3D surface inspection defect “impression” (Source: voestalpine Tubulars)

Thus, a technical upgrade of an existing tube wall measuring system, which is an economically highly interesting option for all PQF and FQM mill operators and users of 2-, 4, 9- or 13-channel wall thickness gauges from IMS Messsysteme GmbH.

The earliest possible detection of surface defects will be an essential requirement in seamless tube production in the future. Even today, high-precision measurement technology can no longer be ignored with without having to call the highest product quality into question.